About ChemTecUSA

Precision. Reliability.

Built into Every Part.

ChemTecUSA is a veteran-founded division of ChemArt, delivering high-precision photochemical machining and milling (PCM) services for over fifty years. Founded in 1976 in Lincoln, Rhode Island, ChemTecUSA has grown into a trusted partner for engineers and manufacturers across the medical, aerospace, electronics, defense, and energy sectors.

Our legacy began with a breakthrough in photoresist chemistry. Company founder Richard Beaupre, an industry innovator, U.S. Navy veteran, and University of Rhode Island graduate, developed the first aqueous dry film photoresist. This patented process revolutionized the PCM process. His forward-thinking approach and the company culture that he built still guide our operations today.

Since opening, we’ve served several thousand clients, ranging from mom-and-pop shops and nonprofits to Blue Chip Fortune 100 companies worth billions.

ChemTecUSA operates from a vertically integrated, 62,000 sq. ft. facility equipped for scale, speed, and precision. We hold ISO 9001:2015 certification and offer complete in-house services, including etching, forming, plating, assembly, and more. This fully integrated approach allows us to reduce lead times, maintain tight tolerances, and give our customers full visibility throughout production.

NEWS

ChemTecUSA

in the News

Our Deep Commitment to Environmental Stewardship

ChemArt, the parent company, has invested in waste reduction, waste treatment, and proper hazardous waste disposal. As a manufacturer in a coastal location, anything disposed of in the state sewer system ultimately ends up in the ocean, putting shellfish and sea life at risk. Rhode Island discharge standards are among the most stringent in the USA, and ChemArt is proud of our company-wide commitment to environmental stewardship and the awards we have received for our efforts.

Our Legacy of Giving Back

ChemTecUSA’s commitment to service extends beyond manufacturing. Mr. Beaupre underwrote a Chemistry and Forensic Science building at the University of Rhode Island that remains in use today, following the lead of our founder, a generous philanthropic partner to many, including the RI Philanthropic Orchestra, United Way, and others. Our team and company have maintained the strong tradition of philanthropy that Mr. Beaupre created—supporting community needs, national initiatives, and nonprofit partners.

Our ongoing partnership with the Spirit of Liberty Foundation has helped fund hurricane and wildfire recovery efforts, including donations of decorative products that brought comfort and hope to affected communities. Closer to home, our staff recently led a company-wide food drive and took on the cleaning, restocking, and reorganizing of the Operation Stand Down food pantry, ensuring Rhode Island veterans and their families had access to essential support.

We also work closely with nonprofit organizations to design and produce custom fundraising gifts and donor recognition awards, helping them meet campaign goals and strengthen supporter relationships. In addition, ChemTecUSA has made a significant investment in The People’s House, an immersive White House experience located just blocks from the actual building, to support civic education and national storytelling.

For us, giving back isn’t a side project—it’s built into who we are.

Why Choose ChemTecUSA

We specialize in producing burr-free, distortion-free metal parts that meet exacting tolerances. Our photochemical machining process creates complex geometries and delicate features without introducing stress, heat, or deformation—making it ideal for high-reliability applications.

At ChemTecUSA, you’ll find:

- Fully integrated services on a single campus

- Support for prototyping, production, and assembly

- Engineering collaboration from concept to delivery

- Fast turnarounds with low-cost tooling

- History of great leadership

- Secure handling of customer-supplied materials

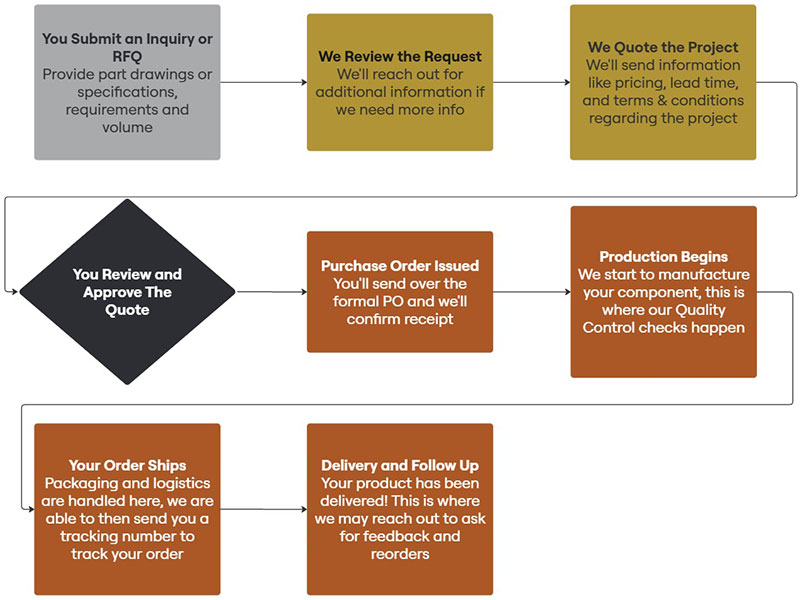

How to Order

Simple, Streamlined Ordering from Quote to Production

Need parts fast? Our ordering process is built for engineers and buyers who don’t have time to waste. We walk you through each step—from quoting and design support to material selection and final production—so nothing falls through the cracks.

Learn how to:

- Submit your drawing or spec sheet

- Get expert input from our engineering team

- Approve your quote and move into production

FAQ’s

Answers to Common Questions About Our Services and Capabilities

Have questions about part tolerances, materials, or how photochemical machining works? Our FAQ page covers all the essentials, plus helpful insights on prototyping, finishes, and compatible metals.

Find out:

- How photochemical etching works

- Which materials we etch and plate

- How we hold precision without burrs or heat stress

- What makes our process ideal for tight timelines and complex designs

NEWS

Industry Insights, Company Updates, and Etching Know-How

Our News page features updates from the ChemTecUSA team, helpful tips for design engineers, and real-world applications of photochemical machining. It’s a great resource to keep up with new capabilities, project highlights, and technical guidance.

Discover:

- Case studies and manufacturing insights

- Design tips and technical articles

- Updates on services and facility upgrades

Inside Our Precision Chemical Etching Facility

ChemTecUSA Plant Tour

Built for Critical Performance

ChemTecUSA is standing by to become a long-term partner in your product’s success. From early-stage development to

In high-volume production, our team delivers parts that meet your specs and exceed expectations.

Contact us today to learn how we can support your next project.