Frequently Asked Questions

Have questions about ChemTecUSA’s capabilities, quality systems, or how to get started?

You’ll find the answers here. This ChemTecUSA FAQs page is designed to address the most common questions from engineers, buyers, and product teams who want to learn what sets us apart in photochemical machining and explore our full range of services as a trusted supplier partner.

We’re known for precision, fast response times, and customer-first service—and we’re here to help you move from concept to finished part confidently.

General Capabilities

Every ChemTecUSA team member is here to make your experience simple, transparent, and productive. You’ll get clear communication, practical engineering input, and production timelines you can count on.

Every project starts with your goals, specs, and constraints. From there, we build a plan around your needs and stay engaged until the job is done. You’ll always know where your project stands.

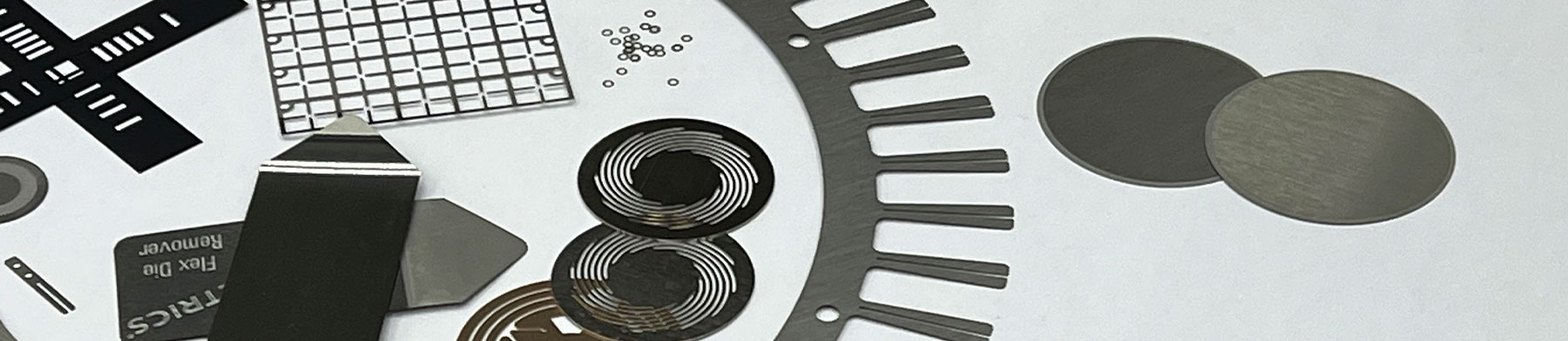

What does ChemTecUSA specialize in?

ChemTecUSA produces high-precision metal components using photochemical machining (PCM). Our process is ideal for parts that require tight tolerances, clean edges, and intricate features—especially in the aerospace, medical, defense, electronics, and energy sectors. Unlike other cutting methods, we do not change the physical properties of your metal during processing.

What’s unique about ChemTecUSA’s process?

We are vertically integrated. That means everything from engineering support and photochemical milling to plating, screen and digital printing, and packaging happens in one U.S.-based campus. This results in fewer delays, fewer risks, and more control over your production timeline.

What makes ChemTecUSA different from other PCM suppliers?

We’re not just a vendor, we’re a partner. ChemTecUSA’s team is hands-on, collaborative, and focused on helping you get parts that work the first time. We’ve been doing this for over half a century, and many of our clients have stayed with us for decades because they trust us to deliver.

Materials & Tolerances

What materials can you work with?

We work with a variety of metals, including stainless steel, copper, nickel alloys, aluminum, molybdenum, and others. We do not work with titanium or flex circuits. We also support customer-supplied materials and sensitive alloys.

How precise are your parts?

We hold tolerances as small as 12.5 microns and can support thin stock down to 0.0005 inches. Typical thicknesses range from 0.0005 to 0.032 inches, depending on the material. Our process produces burr-free, distortion-free parts without mechanical stress.

Can you print on metal or other difficult materials?

Yes. ChemTecUSA can digitally or screen print on unprintable substrates like metal, something most shops can’t do. This proprietary capability allows us to add markings, patterns, or guides directly onto parts that need additional identification or branding.

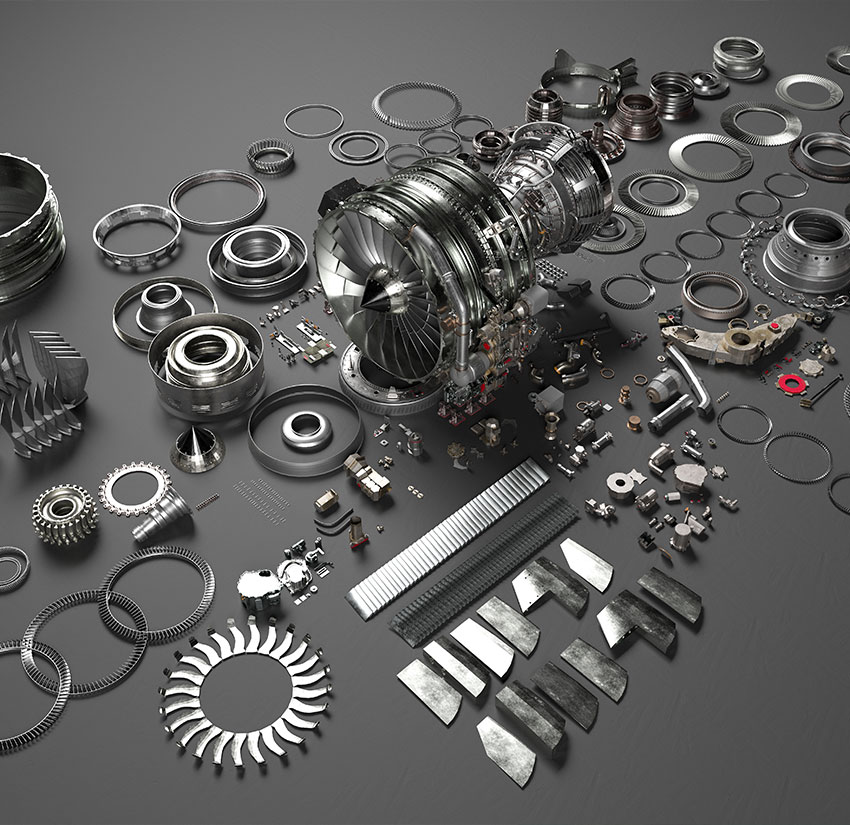

Industries Served

What industries do you serve?

ChemTecUSA serves clients across various industries—from medical and defense to electronics, aerospace, and energy. Whether it’s components for a baby heart monitor, EMI shielding for electronics, or bipolar plates for hydrogen fuel cells, our solutions scale to your application.

How long do customers typically stay with ChemTecUSA?

Many clients have worked with us for over 10 years—some since the 1970s. Whether you’re a Blue-Chip Fortune 100 manufacturer or a growing OEM, we focus on building long-term relationships rooted in trust, quality, and responsive service.

Certifications & Quality

Is ChemTecUSA ISO certified?

Yes. ChemTecUSA is ISO 9001:2015 certified. Our quality systems have been in place since the 1990s, including complete process documentation, internal audits, and robust inspection protocols to ensure consistent part quality.

How does ChemTecUSA support environmental and safety standards?

We operate our in-house wastewater treatment system with continuous monitoring and lab testing. Over the years, we’ve earned a perfect compliance award for discharge limits. We also track lost-time incidents, conduct regular safety audits, and meet state-level safety certifications.

Is ChemTecUSA based in the U.S.?

Yes. ChemTecUSA is located in Lincoln, Rhode Island. Our American-built operations help avoid import risks, reduce shipping delays, and improve part traceability. Engineers choose ChemTecUSA because they know precisely where—and how—their parts are made.

Prototyping & Finishing

Can ChemTecUSA help with prototyping?

Absolutely. Our prototyping services use affordable tooling to provide high-resolution parts quickly—without the cost and lead time of traditional tools and dies. This helps you iterate faster and get into production with confidence.

Do you offer finishing services?

Yes. We offer multiple plating and finishing services, including nickel, gold, rhodium plating, and tin plating for electronics. We also provide blackening for enhanced contrast or optical functionality. Finishing work is done in-house under strict process controls.

CHEMTECUSA

Ordering &

Lead Time

How do I place an order?

Start by requesting a quote. Our team will review your design and get back to you quickly. We’ll help refine your specs, confirm materials and finishes, and guide you through the entire process from design to delivery.

What is your typical lead time?

While we don’t guarantee exact turnaround times online, our in-house team, multi-shift operation, and integrated workflow allow faster response and delivery than traditional machine shops. We’ll give you an accurate estimate with your quote.

Still Have Questions?

If you didn’t find what you were looking for in these ChemTecUSA FAQs, reach out directly. Our team is available to discuss your design, help with material selection, or walk you through the ordering process.