Fuel-Cell Bipolar Plates

ChemTecUSA manufactures precision-etched bipolar plates for hydrogen fuel cells and other electrochemical energy systems. These plates contain carefully designed flow channels that direct gases, manage heat, and enable efficient electrical conduction inside the fuel cell stack. Because performance depends on tight tolerances and corrosion-resistant materials, we use photochemical etching(also called photochemical machining) to produce parts that meet exacting energy industry standards.

Whether you’re developing compact systems for portable power or large-format stacks for industrial or transportation use, ChemTecUSA delivers reliable, production-ready solutions.

What Bipolar Plates Do

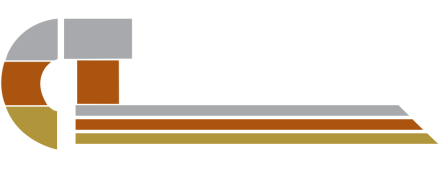

Bipolar plates are essential in PEM (proton exchange membrane) and other fuel cell designs. Each plate sits between two membrane electrode assemblies (MEAs), channeling hydrogen and oxygen to the catalyst while conducting electrical current through the stack. The plates also manage water, remove heat, and help distribute pressure evenly across the cell.

The geometry of the flow field and the accuracy with which it’s produced impact how efficiently the fuel cell operates.

Advantages of

Etched Bipolar Plates

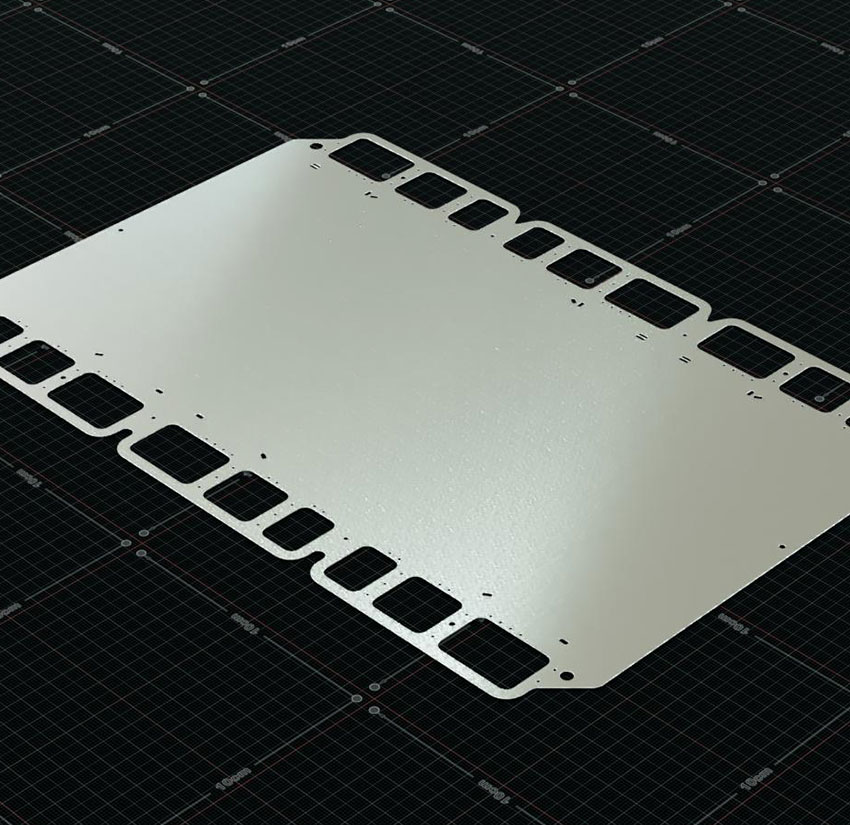

Unlike stamping or milling, chemical etching allows you to create complex flow-field patterns without stressing the metal or altering its surface properties. This material integrity is essential when working with thin-gauge plates and corrosion-resistant alloys.

ChemTecUSA’s process supports:

- Burr-free flow channels with sharp corners and clean walls

- Intricate, high-resolution designs with precise depth control

- Uniform metal thickness for even conductivity and thermal transfer

- No tool wear or distortion, even on thin metals

- Fast iteration of design changes and prototyping

We commonly work with stainless steel, nickel-based alloys, and other materials suited for fuel cell environments.

CHEMTECUSA

Designed for

Efficiency and Scale

Because organizations use large quantities of bipolar plates in a single project, large-scale uniform production is key. ChemTecUSA uses photoresist tooling and precision-controlled etching baths to ensure consistent channel dimensions and alignment from plate to plate. That means reliable flow performance and uniform current distribution across the entire system.

We can produce:

- Interdigitated, serpentine, and custom flow channel layouts

- Plates with integrated ports, notches, or alignment features

- Designs compatible with compressed, sealed, or welded stacks

- Plates for both single- and dual-flow field configurations

Need a low-profile, lightweight fuel cell? We can help optimize your layout to reduce material use while maintaining performance.

Supporting the Future of Clean Energy

Bipolar plates are a growing part of clean energy infrastructure, from automotive hydrogen powertrains and backup power systems to portable electronics and off-grid applications. As demand for fuel cells rises, so does the need for trusted component suppliers who understand the manufacturing challenges. ChemTecUSA brings over half a century of photochemical etching expertise to help energy innovators prototype, test, and produce bipolar plates.

Contact us today to discuss your next high-efficiency bipolar plate project.