Custom Nameplate & ID Tags

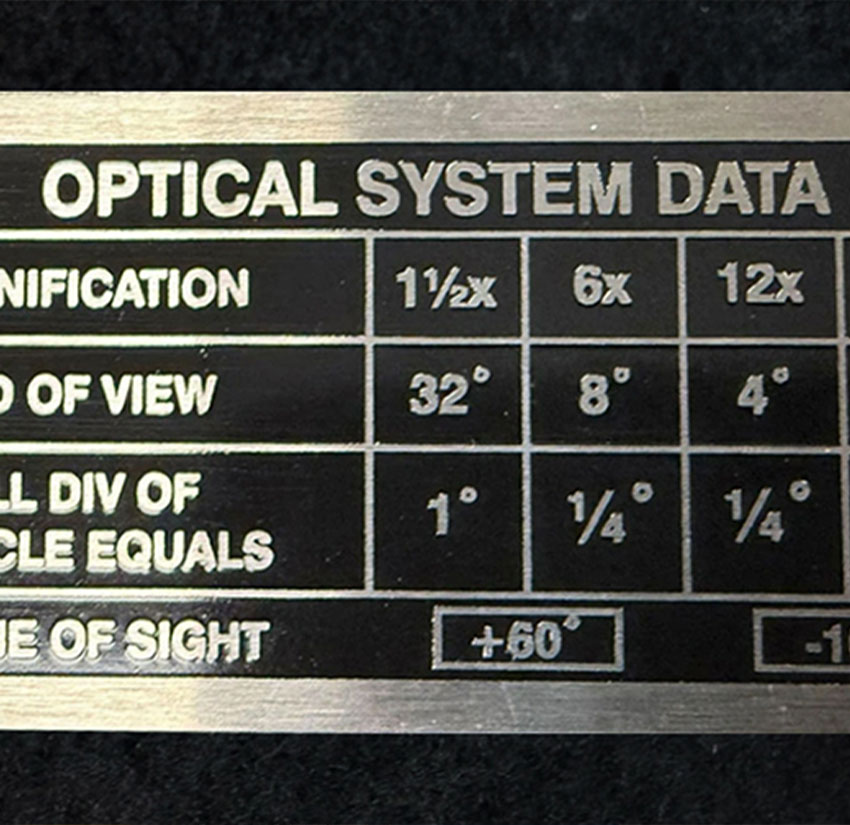

ChemTecUSA manufactures high-quality nameplates and ID tags using photochemical etching, delivering sharp detail, strong contrast, and long-lasting durability. Whether you need permanent branding, traceability, or compliance markings, our process provides clean, burr-free designs that withstand harsh environments. These etched tags are used across aerospace, defense, industrial, and OEM markets where identification must remain readable over time.

Why Choose Etched

Nameplates?

Photochemical milling (PCM) is ideal for metal tags that need to look sharp and stay readable for years, even in outdoor or industrial use. The PCM process removes material precisely, creating smooth, recessed text or graphics that won’t wear away with handling, heat, or abrasion. These plates can be adhesive-backed, drilled, or cut with custom shapes to match your assembly process.

Compared to other methods, like engraving, photochemical etching offers:

- Finer detail and more control over line thickness

- Lower cost for multi-part or high-volume runs

- No distortion or stress, even on thin or delicate materials

- Cleaner, smoother surface finishes—great for safety, readability, and durability

Photochemical milled nameplates are better suited for curved or flexible parts because the process doesn’t weaken the metal. They’re ideal for heat, chemicals, or repeated cleaning applications.

Materials and Options

We etch nameplates in a wide range of metals and finishes:

- Stainless steel: Durable and corrosion-resistant for industrial and medical use

- Aluminum: Lightweight with strong contrast for outdoor or OEM branding

- Brass or bronze: Decorative and classic for architectural or high-end applications

- Nickel and specialty alloys: Available for defense or electronics tags

We can add finishes like black oxide, gold, or tin plating to meet appearance or performance needs. Text, barcodes, serial numbers, and logos can all be etched with tight control over layout and line weight.

Common Applications

ChemTecUSA produces etched ID tags and plates for:

- Aerospace parts, tools, and assemblies

- Defense equipment and weapons systems

- Industrial machinery and control panels

- Medical device labeling and asset tracking

- Nameplates for brand identity or compliance

- Serialized and barcoded inventory tracking

Etched vs. Engraved Tags: What’s the Difference?

Etched nameplates are created by chemically removing material, allowing for fine detail without surface damage or stress. Engraved plates are cut mechanically or with a laser, which can leave burrs or distortion—especially on thin or hard metals.

Photochemical etching is more cost-effective for complex designs, small text, or larger batches, while engraving is better suited for deeper marks or tactile features. If you need high precision, clean surfaces, or a fast turnaround on repeatable designs, PCM is the better choice.

CHEMTECUSA

Custom Name Plates

& ID Tags That Last

ChemTecUSA tags are made to perform, not just display. Every plate we produce is inspected for clarity, alignment, and etch depth to ensure it meets your functional and visual standards. Whether you need one prototype or thousands of serialized tags, we’ll help you find the right size, finish, and attachment method.

Whether you’re developing a compact encoder for embedded control or a high-resolution disk for a complex axis, we’ll build it to your specifications.

Need ID Etched ID Tags That

Hold Up In Harsh Environments?

Send us your design or spec, and we’ll help you create a nameplate that’s easy to read—and built to last.