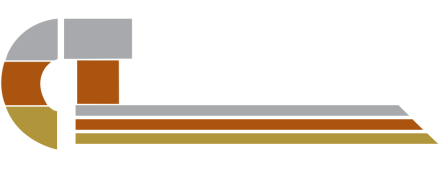

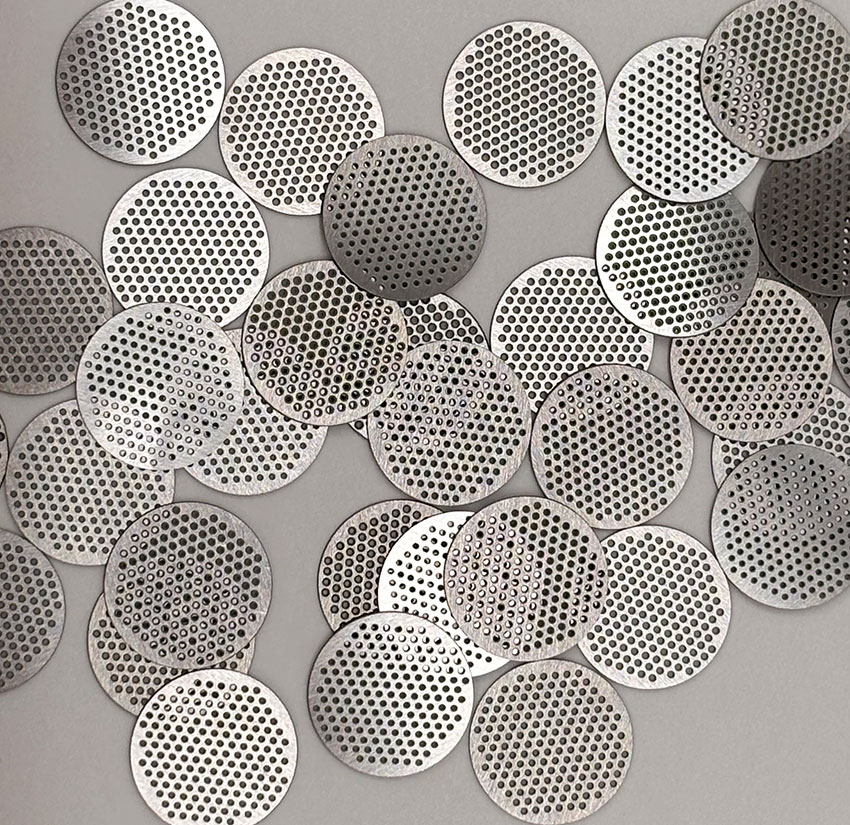

Metal Mesh & Filter Screens

ChemTecUSA produces custom filter metal mesh and precision screen components using photochemical etching. These etched parts are designed for consistent flow control, reliable filtration, and long-term durability in demanding environments. Unlike woven or stamped options, our flat metal screens deliver accurate openings, clean edges, and stress-free performance, which is ideal for applications where precision matters more than bulk.

While the names “filter” and “screen” may be used interchangeably, they serve slightly different purposes. Screens are designed to block or separate larger particles using evenly spaced openings, often for flow regulation or particle exclusion.

Filters capture smaller particles or contaminants from liquids or gases, often requiring tighter tolerances and finer openings. ChemTecUSA manufactures both, with custom patterns and materials matched to your application’s precision and performance requirements. Whether you’re filtering fluid, gas, or particles, ChemTecUSA screens and filters help ensure efficiency and reliability at every stage.

Photo Chemical Etched Screens for Clean, Accurate Flow

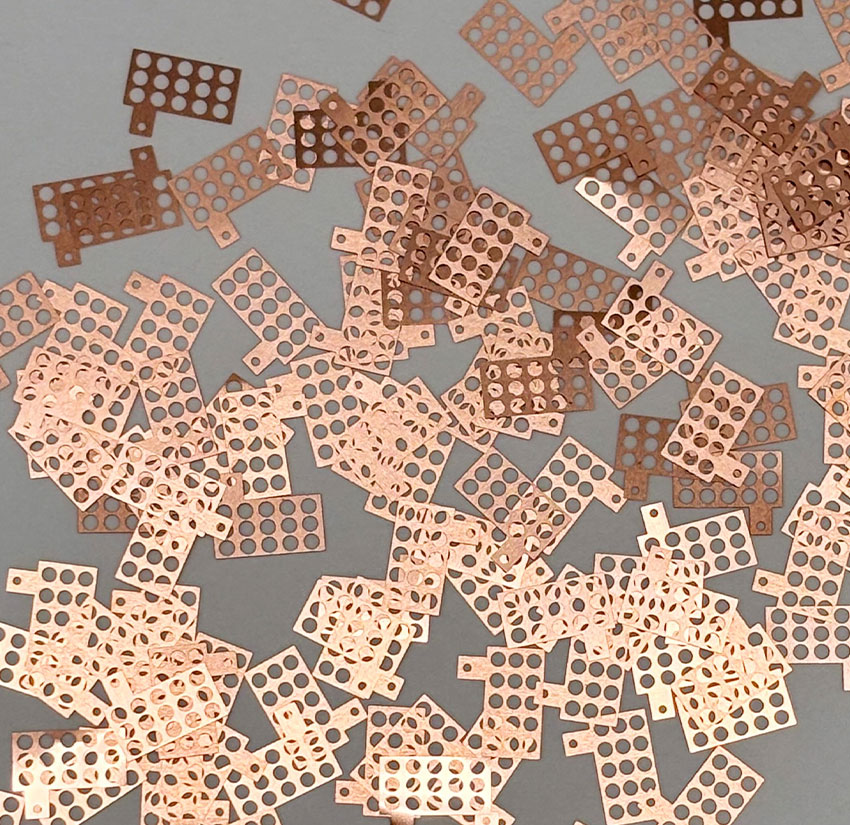

Etched metal mesh offers clear advantages over traditional mesh and perforated materials. Because chemical etching doesn’t rely on force or heat, the resulting apertures are free from burrs, deformation, or mechanical distortion. This means each opening performs as intended by reducing clogs, preserving flow rates, and eliminating variation across the surface.

Benefits of etched filter screens:

- Consistent hole size and placement across the full pattern

- Flat surfaces that prevent particle buildup and stretching

- No burrs, sharp edges, or stress fractures

- Precision designs for complex geometries or irregular shapes

- No loss of material strength, even in thin foils or high-density layouts

Whether you need micro-scale filtration or open-area screens, our team can help you develop the right mesh solution from prototype through production.

Custom Metal Mesh for Specialized Applications

Our customers trust ChemTecUSA’s PCM screens and filters in systems that demand high performance with low variation. Typical uses include:

- Medical devices – blood filtration, fluid control, and diagnostic screens

- Aerospace systems – vents, EMI shielding, and contamination filters

- Industrial equipment – particle screens, flow restrictors, and strainers

- Consumer products – appliance filters, mist separators, and spray control

- Energy systems – fuel and hydrogen filtration, airflow screens, and gaskets

We support both functional and decorative designs, and we can photochemically etch nearly any pattern into metal, including custom apertures, branding, or part identification.

Why Etch Instead of Stamp or Weave?

Stamped screens often introduce warping, burrs, and tool wear, reducing part reliability, especially in delicate patterns or thin metals. Woven meshes can stretch or shift during use, leading to inconsistent filtration and faster clogging.

With chemical etching, there is no:

- Tooling wear or edge rounding, so holes stay sharp and clean

- Mesh shift or weave distortion because materials remain flat and stable

- Restrictions on aperture count or layout

- Hard tooling costs, making it ideal for prototypes or short runs

ChemTecUSA’s process creates all features simultaneously, meaning even high-density layouts can be produced without extra setup time or expense.

CHEMTECUSA

Materials and

Capabilities

We produce filter screens from corrosion-resistant and high-strength materials, including:

- Stainless steel

- Nickel

- Copper

- Brass

- Aluminum

- Beryllium copper

- Customer-supplied alloys upon request

Typical thicknesses range from 0.0005 to 0.032, depending on the material and application. Etched designs include a variety of custom features, including through holes, partial openings, branding, or precision cutouts.

Need Reliable Photo Chemical

Machined Filtration Devices?

Contact us today to learn how ChemTecUSA can support your next screen or filter project with cleaner, more consistent results.