Stator & Rotor Encoders

ChemTecUSA manufactures precision-etched stator rotor encoder components for highly accurate motion control systems. These parts are essential for converting rotational motion into electrical signals that enable machinery to monitor position, direction, and speed in real time. Our chemical etching process supports the fine lines, intricate geometries, and dimensional accuracy required for modern encoder disks and rings without warping, burrs, or surface damage.

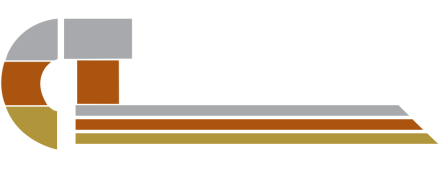

How Encoders Work

Rotary encoders, also called shaft encoders, measure rotation and convert that motion into a digital signal. As the rotor spins, the stator detects changes in a precisely etched pattern using light, magnetic fields, or inductive sensing. This movement indicates how far something has turned, how fast it’s moving, or what direction it’s spinning. Encoders are essential wherever precise motion tracking and repeatable control are required.

You’ll find encoder systems in:

- Robotics, where they track joint movement and tool positioning

- Industrial motors, for real-time speed and torque control

- Computer mice and trackballs, translating small hand movements into cursor control

- Medical devices, such as powered surgical tools and imaging systems

- Aerospace navigation, where precise feedback helps stabilize and direct control systems

Built for Signal Accuracy

& Mechanical Stability

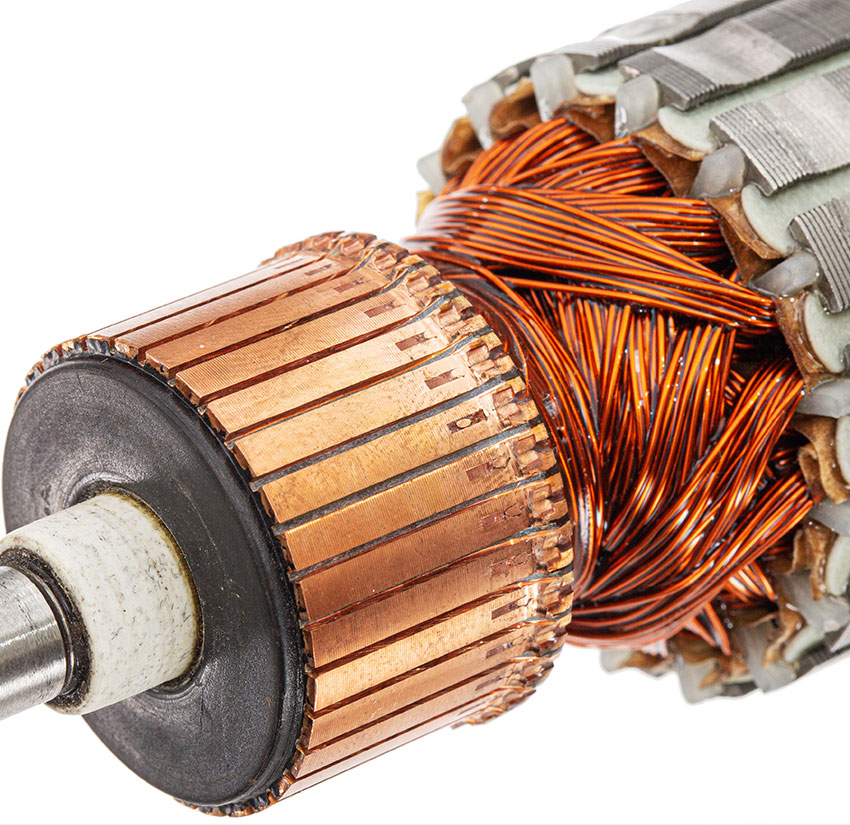

Encoders rely on a rotor (a rotating disk or ring) and a stator (the fixed sensor component) to detect motion. Whether using light, magnetic fields, or inductive signals, this interaction depends on clean, consistent patterns that won’t drift, misread, or degrade over time.

ChemTecUSA’s etching process delivers micron-level resolution, enabling fine-pitch line densities for both incremental and absolute encoder formats. We hold tolerance to 25 microns with exceptional edge definition essential for maintaining clean transitions and signal output.

Optimal Flatness &

Thickness Control

Flatness and material consistency are critical to the performance of stator and rotor assemblies. Uneven surfaces or thickness variations can affect air gaps, optical signal paths, or magnetic coupling. At ChemTecUSA, we maintain tight tolerances on material flatness and gauge to ensure your encoders remain accurate across the full rotation range.

ChemTec USA Advantages for Encoder Manufacturing

- Ultra-precise line definition for sharp, high-resolution signal output

- Smooth, burr-free patterns to prevent light scatter and jitter

- Controlled reflectivity options, including matte, polished, or blackened surfaces for optical tuning

- Corrosion-resistant materials for stability in harsh environments

- Consistent concentricity and center hole placement for simplified assembly

- Support for optical, magnetic, and inductive encoder designs

We work with stainless steel, nickel, and other alloys to match the requirements of your specific encoder system.

ChemtecUSA’s Durable Encoders Provide Clean Signals

Because etched encoders produce more consistent transitions than stamped or laser-cut parts, they generate less noise and cleaner pulses, especially at high speeds. That makes them ideal for servo systems, robotics, and other motion-critical environments where stability and low jitter are non-negotiable.

We also offer custom finishes to adjust reflectivity based on the encoder’s sensing method. Performance-driven finishes include creating a high-contrast surface for optical readers or a non-glare surface for camera-based detection.

CHEMTECUSA

Applications We Support

- Industrial automation feedback systems

- Precision motor control for robotics

- Surgical and diagnostic positioning devices

- Aerospace and defense motion tracking

- Laboratory instrumentation and test rigs

Whether you’re developing a compact encoder for embedded control or a high-resolution disk for a complex axis, we’ll build it to your specifications.

Partner with ChemTec USA to Create

High-Quality Rotor & Stator Encoders

Reach out today to discuss your project with ChemTec USA’s experienced team.