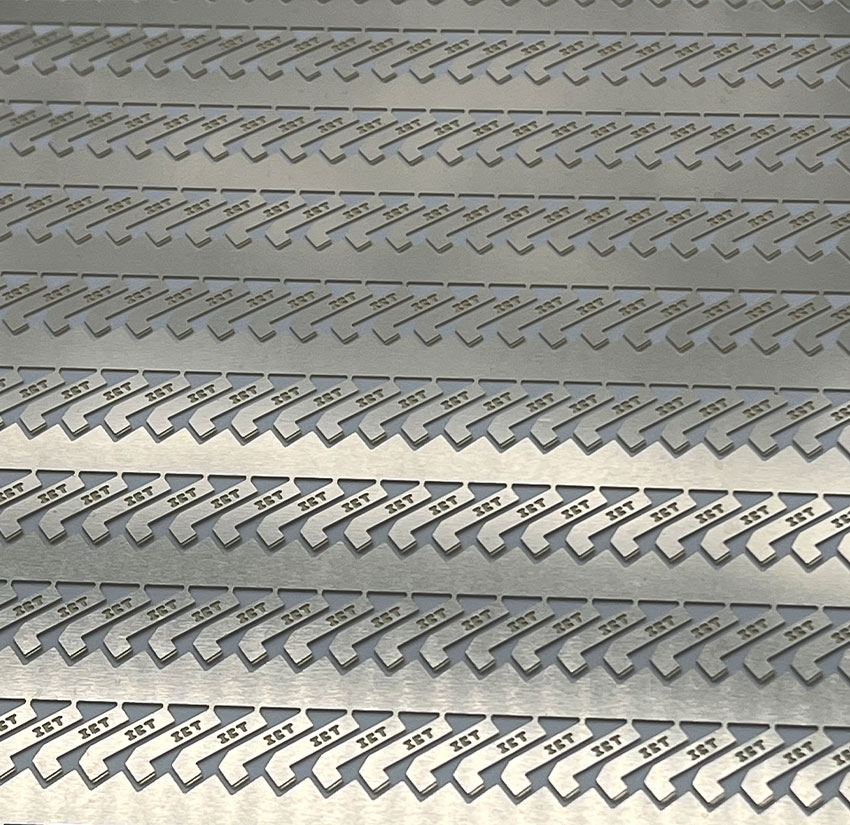

High-Precision Surgical Blades

ChemTecUSA manufactures surgical blades using photochemical etching to achieve razor-sharp edges, clean finishes, and consistent dimensional control. Traditional stamping or grinding methods can warp, stress, or dull thin metals. Our process preserves the blade’s integrity throughout production. That means smoother cuts, better performance, and higher repeatability without distortion or brittleness that undermines performance. Medical device manufacturers trust ChemTecUSA for sharp-edge components that meet critical specs and tight timelines.

Why Chemically Etched

Blades Make a Difference

Photochemical milling removes unwanted material without applying heat or mechanical force. This process is ideal for crafting thin, high-precision blades. Chemical etching is a non-invasive process that preserves the metal’s internal structure. Quality control is easier because this method does not produce hardened edges, surface cracking, or unwanted bends.

With our PCM process, you get:

- Clean, burr-free cutting edges

- Stable, flat blades with no heat distortion

- Repeatable geometry for consistent performance

- No risk of stress fractures or brittle edges

- Tight tolerances for surgical accuracy

This comprehensive process makes chemically etched blades preferred for minimally invasive tools, diagnostic devices, and precise surgical applications.

Consistently Engineered

for Medical Precision

We work with biocompatible materials, including stainless steel, nickel alloys, and specialty grades suitable for sterilization and surgical use. We offer various metals for each surgical blade to ensure optimal sharpness, durability, and safety.

Common features of our chemically machined surgical blades include:

- Micro-sharpened points or tips

- Serrated or straight edges

- Custom profiles for cutting or scraping

- Mounting holes or tabs

- Printed identifiers or part numbers

If your blade is part of a disposable assembly or multi-part tool, we can help integrate features that support alignment, packaging, or downstream assembly.

DESIGNED FOR

Scale and Speed

From prototype to high-volume production, ChemTecUSA builds surgical blades with speed and consistency. Our low-cost tooling and quick turnaround make it easy to test and refine your design before moving to larger batches. Once approved, your blade can go directly into production using the same process and specifications.

We can also incorporate forming, plating, and screen or digital printing if your blade design includes bends, coatings, or markings. ChemTecUSA completes each step in-house, eliminating the extra time and cost of sending your surgical blades to multiple vendors for finishing.

Consistency You Can Count On

Every blade we make is inspected for dimensional accuracy and edge quality. Our ISO 9001:2015-certified quality processes ensure traceability and compliance from raw materials through final shipment. Whether you need a few prototypes or ongoing production support, ChemTecUSA delivers reliable results with no surprises.

Let’s build your next surgical blade with precision from the start.