ISO 9001:2015-Certified Quality Management

ChemTecUSA’s commitment to quality runs through every part we manufacture, every process we run, and every order we ship. With ISO 9001 certification since 1995, we maintain a documented, disciplined approach to precision manufacturing that prioritizes consistency, accuracy, and customer satisfaction. You can trust us to deliver high-performance parts built to meet your specs and schedule.

Built on a Legacy of Precision

As a division of ChemArt, ChemTecUSA has carried forward a legacy of quality innovation since 1976. From our earliest photochemical machining processes to our current in-house production model, we’ve emphasized quality at every level—from design support and tooling setup to inspection and delivery. Each department is accountable to our quality standards, and every team member is trained to identify and address risks before they affect your parts.

What ISO 9001:2015

Means for You

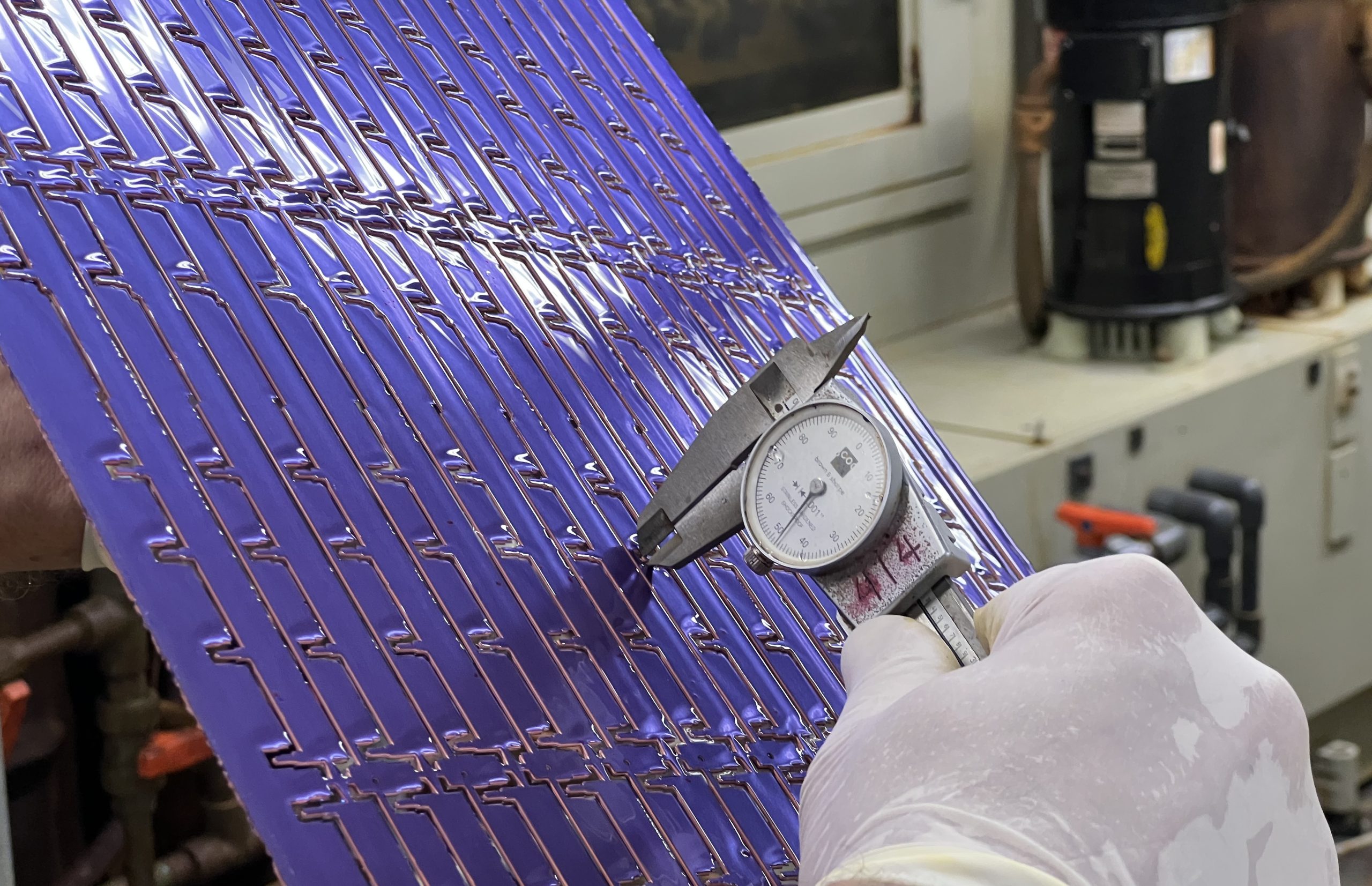

Holding ISO 9001:2015 certification verifies adherence to the highest standards of internal checks, data-driven improvement, and operational discipline. We routinely produce etched parts that require clean edges, tight tolerances, and zero room for error.

Certification is issued by an ANAB-accredited management systems certification body and recognized under the IAF Multilateral Recognition Arrangement. ChemTechUSA regularly conducts multi-layer internal and external audits. We have been ISO certified since 1995.

Our Quality Management System supports:

- Continuous improvement across departments and processes

- Validated metrics that track key performance indicators for every job

- Material traceability and inspection documentation are available upon request

- Process control to reduce variation and increase repeatability

- Customer feedback loops that inform product and service adjustments

From Engineering

to Final Inspection

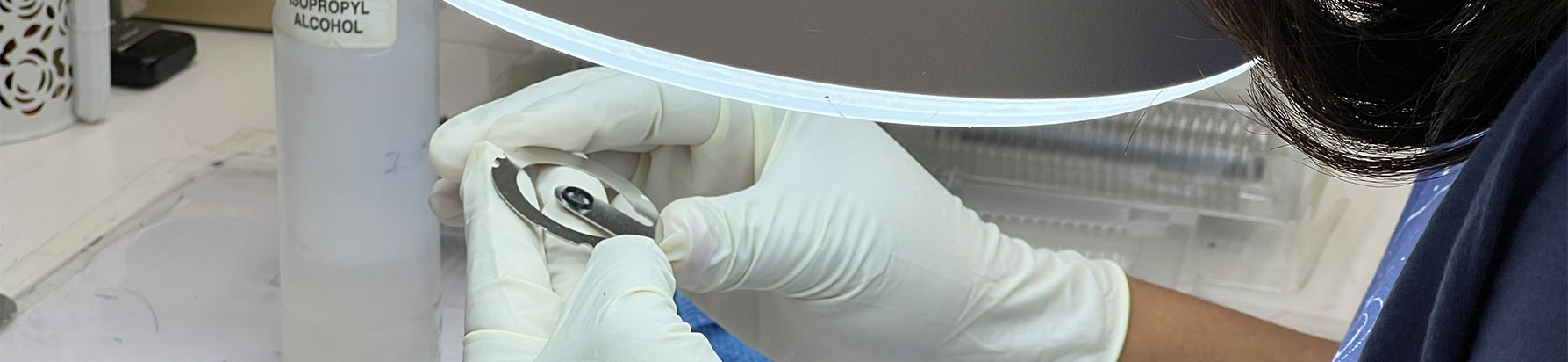

Quality starts in our quoting and engineering process. We review your part requirements up front to align on specs, tolerances, materials, and finishing options. As your order moves through our facility, every stage—from chemical etching to plating and forming—is documented, monitored, and reviewed against our internal benchmarks and your supplied requirements.

Our floor teams use calibrated tools and controlled inspection procedures to verify part dimensions and surface conditions. Material certifications and inspection reports can be included with your order when needed for validation or compliance purposes.

CHEMTECUSA

ChemTecUSA’s Culture of Accountability

Everyone at ChemTecUSA understands that quality is a shared responsibility and a long-term commitment to serving our customers well. ChemTecUSA trains all employees to spot quality issues early and suggest process improvements. This culture of accountability extends to every corner of our facility, enabling us to prevent defects, meet lead times, and exceed expectations without incurring additional costs or delays.

High Accuracy for Critical Components

Quality starts in our quoting and engineering process. We review your part requirements up front to align on specs, tolerances, materials, and finishing options. As your order moves through our facility, every stage—from chemical etching to plating and forming—is documented, monitored, and reviewed against our internal benchmarks and your supplied requirements.

Our floor teams use calibrated tools and controlled inspection procedures to verify part dimensions and surface conditions. Material certifications and inspection reports can be included with your order when needed for validation or compliance purposes.

Send us your drawings and request a quote today.