Photochemical Etching Expertise

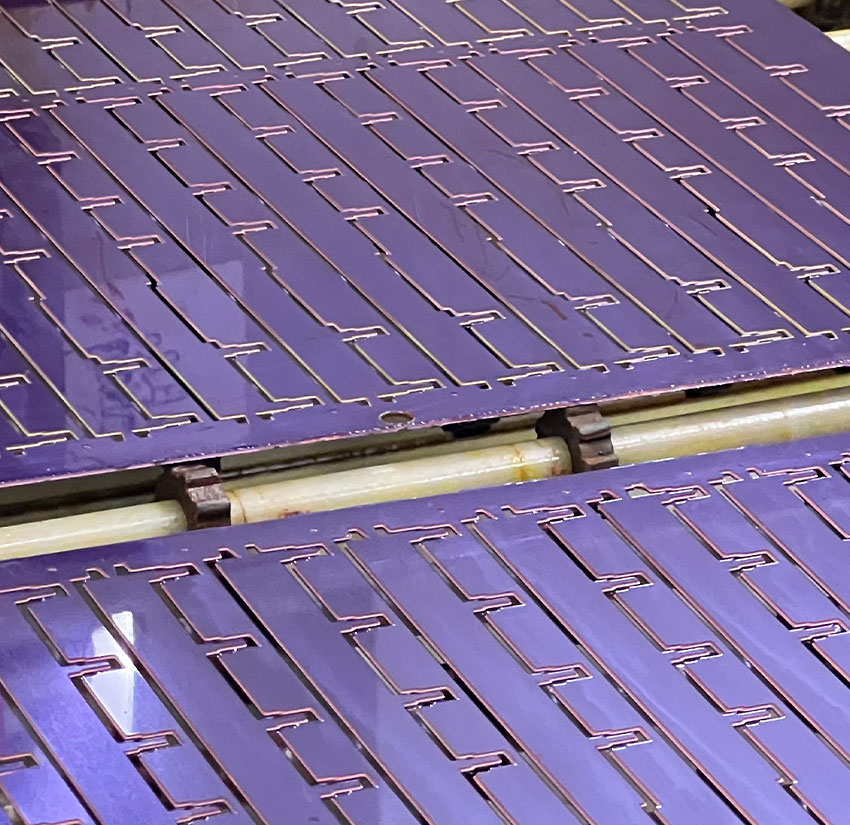

ChemTecUSA provides precise chemical etching for metal components for medical, aerospace, defense, energy, and electronic systems. Our photo chemical machining process produces clean, burr-free parts with sharp features and tight dimensional control. This type of etching does not create the distortion typically seen in stamping, laser cutting, or mechanical tooling.

We support complex part geometries and specialty metals with an in-house process that also includes forming, plating, drilling, laser engraving, and both screen and digital printing. From raw material to finished part, ChemTecUSA delivers production-ready results with speed and accuracy.

Why Choose Photo

Chemical Machining (PCM)?

Chemical etching (also known as photo chemical machining) uses photoresist imaging and a controlled acid bath that removes unwanted material. Chemical etching does not require heat or cause excessive stress that can distort the metal. These differences make chemical etching ideal for applications where precision and part integrity matter.

Key advantages include:

- No burrs, mechanical distortion, or heat-affected zones

- Tooling produced quickly and at a low cost

- Clean, repeatable detail in thin metals and micro-features

- Consistent quality across high-quantity runs

- Short lead times and fast design changes

Whether you’re working with stainless steel, copper, beryllium copper, Kovar, or specialty alloys, our team can help you design and produce etched parts that meet your application needs.

What We Can Etch

Our process supports a wide range of part types, including:

- Encoder disks and shielding for electronics

- Screens, filters, and bipolar plates for energy and fluid systems

- Washers, springs, and spacers for industrial assemblies

- Surgical blades, diagnostic grids, and lab hardware

- Branding plates, tags, and ID markers

Etched parts can be flat or formed, and we offer edge rounding, marking, plating, and other secondary services to meet your specs.

Integrated

Secondary Capabilities

Unlike many providers, ChemTecUSA performs additional steps in-house to complete your part without sending it out for finishing. After etching, your component can move directly into:

- Screen and digital printing for branding, labeling, or functional graphics

- Forming and bending to convert flat patterns into shaped parts

- Plating and coating for protection or conductivity

- Drilling and chamfering for mechanical fasteners or advanced tolerancing

- Laser engraving for added features or hybrid production

Keeping the entire process under one roof reduces turnaround times and ensures quality at every stage.

BUILT FOR

Speed and Scalability

Chemical etching is perfect for early-stage prototyping and just as effective at high-volume production. Our photo tooling setup makes testing multiple designs or fine-tuning features easy before scaling up. Once finalized, we can reproduce your part with high repeatability across thousands of units.

ChemTecUSA’s 62,000 sq. ft. facility in Lincoln, Rhode Island, is optimized for fast processing and responsive scheduling. We serve OEMs and engineers who need consistent quality, clear communication, and on-time delivery—every time.

Looking for a Cleaner, Faster Way to

Build Precision Metal Parts?

Send us your drawings and request a custom quote today.