Rapid Prototype Services

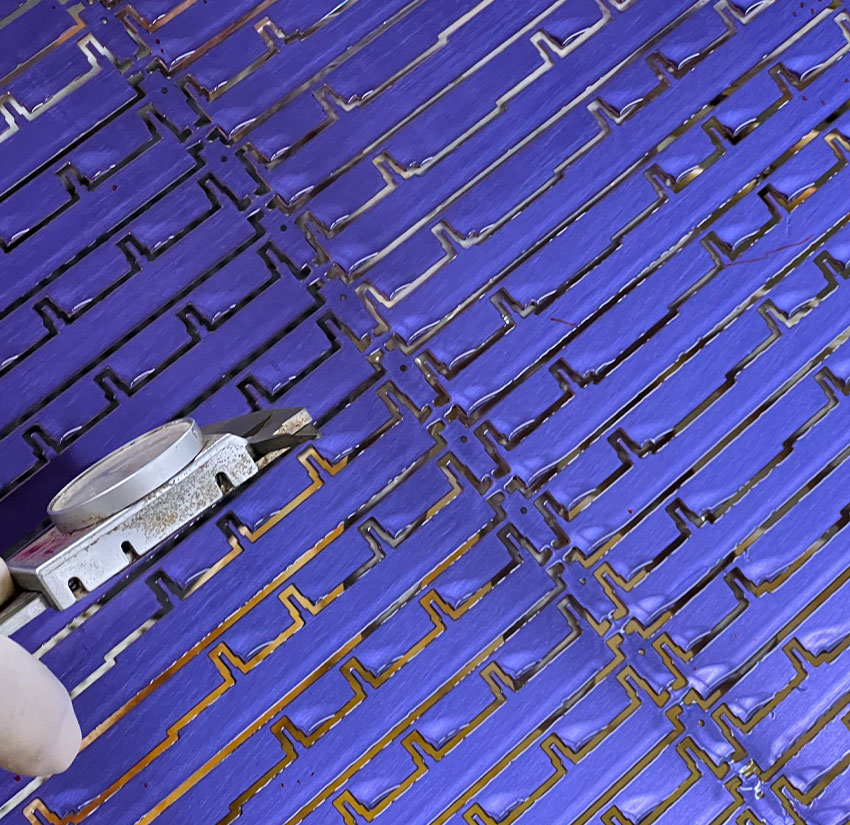

ChemTecUSA offers cost-effective rapid prototyping services to assess, test, and refine metal components before production. Our photochemical machining process allows you to create burr-free, high-precision prototypes without the long lead times or tooling costs of traditional methods. Whether you’re launching a new part or revising an existing one, we help you move quickly and make informed design decisions.

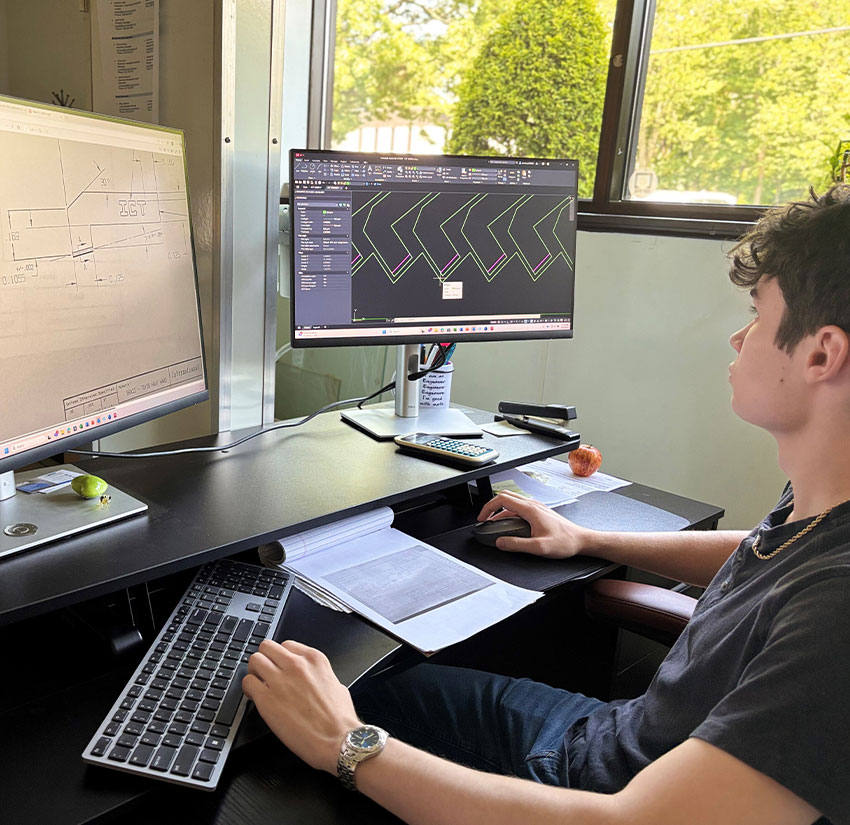

Our team works closely with engineers and product teams across industries to reduce development time and improve manufacturability early in the process.

Prototypes Built for Fast, Cost-Effective Production

We understand that time matters during development, and ChemTecUSA’s rapid prototyping services are designed for speed. Cost-effective prototyping with parts delivered quickly to get your product to market fast. Because we use photo tooling instead of hard dies, it’s easy to revise patterns, test new dimensions, or create multiple design versions without starting from scratch.

This flexibility supports early testing, quick design feedback, and faster approval cycles—saving time on both the front and back end of production.

What You Can

Prototype With Us

Our prototyping services support parts made from stainless steel, copper, beryllium copper, nickel, and other alloys.

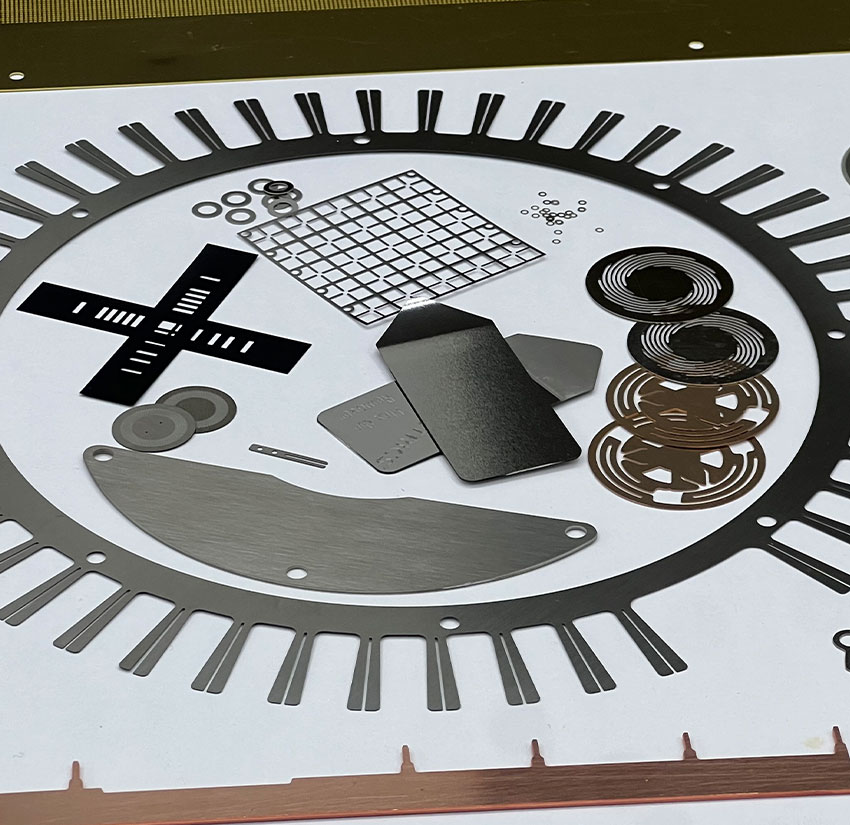

We commonly prototype:

- Sharp-edge components like surgical blades

- Encoders, screens, and flow plates

- Electrical contacts and shielding elements

- Brackets, washers, springs, and spacers

- Custom enclosures or housings

Each part is made to the same quality standards we use in full production. You get real data on form, fit, and function without the cost of full tooling or outside fabrication.

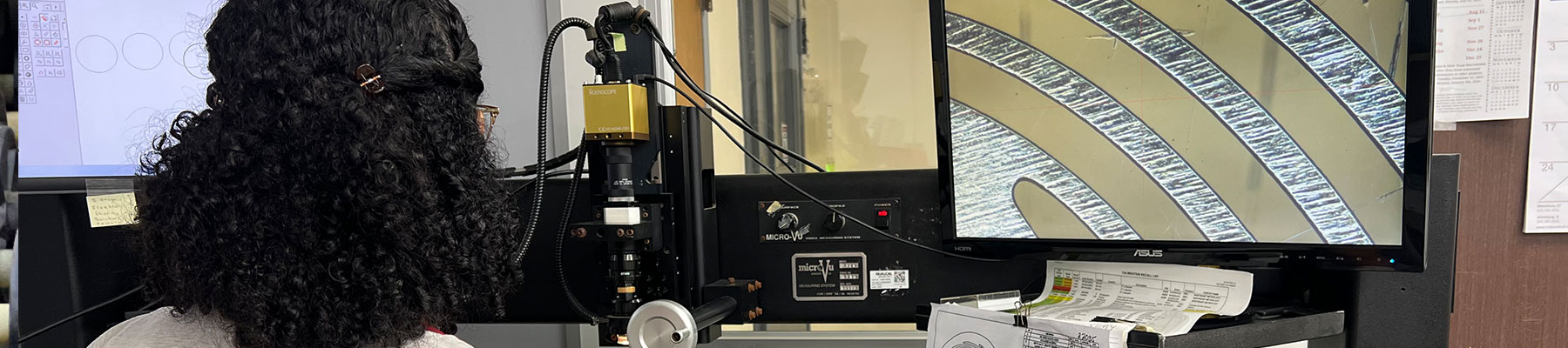

Expert Engineering

Support Included

We don’t just run your file and ship parts. ChemTecUSA’s engineers review your drawings and work with you to understand your goals, tolerances, and material needs. We’ll provide feedback to help optimize your design for etching and future scaling.

If you’re unsure how to prepare your file or how the part will behave in metal, we’re here to help. Our hands-on approach is one more reason why OEMs and engineers choose ChemTecUSA as a long-term development partner.

MOVE FROM

Prototype to Production With Ease

When your prototype is approved, we’re ready to move directly into production using the same in-house processes. Because we control everything from tooling to finishing, you avoid delays, miscommunication, and unnecessary changes when it’s time to scale up.

By prototyping with us first, you ensure a smoother path to launch and fewer issues once volume increases.

ChemTecUSA Is Here to Help

You Move From Concept to Component

Contact our team today, and we’ll help you get a quote, refine your specs, and get prototypes quickly.